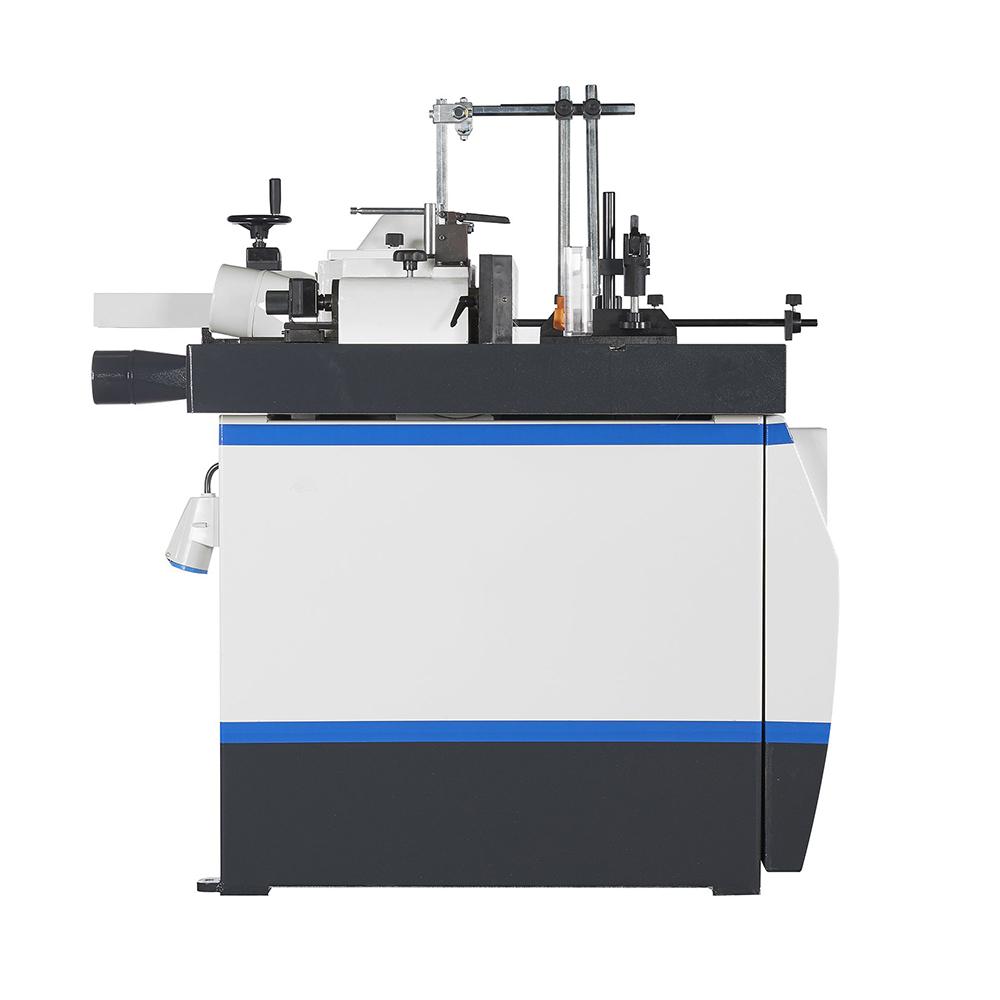

IRONWOOD TS750 Tilting Shaper

The IRONWOOD TS750 Tilting Spindle Shaper caters to the American craftsman as it offers unparalleled smooth cutting operations and performance. This machine features a large, heavy-duty cast iron ground and polished table with insert rings to ensure maximum rigidity and stability for heavy cutting operations. The Ironwood TS750 shaper highlights a backward tilting interchangeable spindle, quick set-up and adjustments, and maximum stability and precision.

- 1 ¼” interchangeable spindle, but can also be fitted with ½”, ¾”, 1”, 30 mm and 35 mm sizes

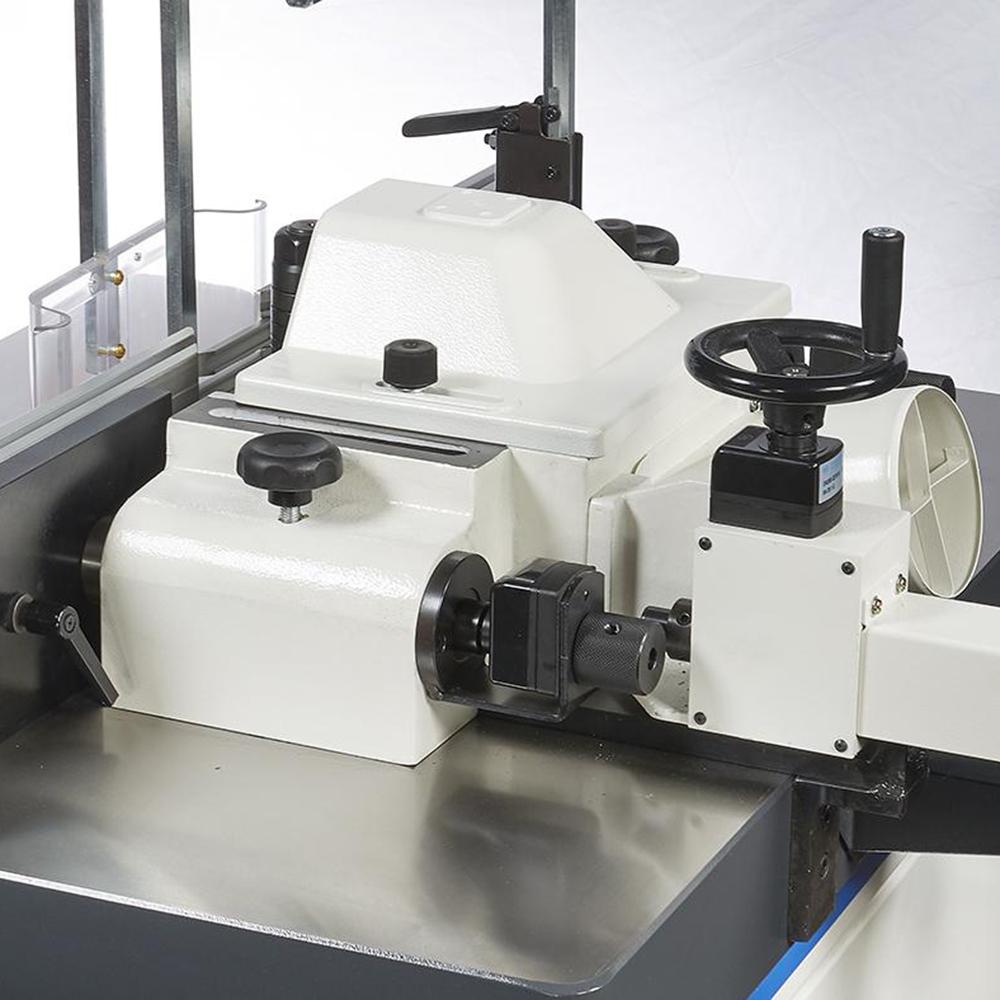

- Backward tilting spindle provides angled cutting from 10° to -45° with angle indicator, and is adjusted with the side-panel handwheel adjustment

- Increased table sizes provide users with additional support when working with larger, more cumbersome work pieces

- Driven by a manual 5-speed, dynamically balanced, v-belt pulley system for speeds of 3000/4000/6000/8000/10,000 RPM

- Heavy-duty, cast iron fence assembly features halves that can be precisely adjusted by a micro-metric adjustment knob

- Dependable, fence assembly with fine-adjustments and digital readouts on both the infeed and outfeed

- Innovative adjustable guide finger design to provide additional support for the work piece as well as safer operations as the operator passes material through the cutter

- Quick, manual speed adjustments and are conveniently located through the front panel of the shaper

- Spindle speed indicator lights to assist the operator within the control panel

- Ironwood’s tooling assembly is precisely designed and constructed to secure absolute precision and greater cutting consistency, the spindles are dynamically balanced for extra smooth running at high speeds

- Cast iron miter gauge and hold-down device for improved user operations

- Spindle hand wheel controls for the rise, fall, and tilt are conveniently positioned on the side of the machine with digital indicators

- Operational controls are located within the centralized control panel and include all major control functions:

- Forward and reverse spindle rotation with a directional indicator light to ensure safe climb-cutting operations

- Spindle speed indicator lights

- Power on/off switches

- Electric spindle brake

- Spindle Lock – with limit switch safety, prevents the machine from starting when engaged

- Spindle Protection Guard

- Emergency Stop

- All electrics are UL and CSA approved

- One year warranty

|

Working table |

960 mm x 1300 mm |

|

Table height |

900 mm |

|

Vertical spindle stroke |

180 mm |

|

Under the nut |

160 mm |

|

Speeds |

5 Speeds (3000, 4000, 6000, 8000, 10000 RPM) |

|

Spindle height adjustment |

Handwheel |

|

Spindle position display |

Mechanical Readout |

|

Tilt adjustment |

Handwheel |

|

Spindle tilt |

10° to -45° (BACK) |

|

Spindle size |

1.25″ x 6″ |

|

Spindle rotation |

Fwd / Rev |

|

Max tool diameter (below table) |

310 mm |

|

Max tool diameter (above table) |

360 mm |

|

Motor |

7.5 HP IE3 |

Shipping dimensions |

1400 x 1292 x 1400 mm |

Shipping weight |

1,650 lbs |

Dust Extraction |

5”/ 4” |

|

Electrical Connection* |

230 Volts | 3-phase | 60 Hz. |

*460V power upgrades available upon request. Additional charges may apply.