IRONWOOD SL300 Sliding Table Saw

IRONWOOD’s SL series of sliding table saws brings ultimate flexibility and versatility to an intuitive cutting solution. Designed to be a blend of innovation, dependability, and quality, the SL series delivers the quality and precision required for the final chip-free cut, improving the results of subsequent machining (i.e. edge-banding, drilling, etc.). This reduces assembly time, as parts fit easier, material costs are reduced, and the need for other machinery can be eliminated. Ideal for panel and solid wood processing, the series is capable of making perfect miters, as well as rip, jointing, and cross cuts.

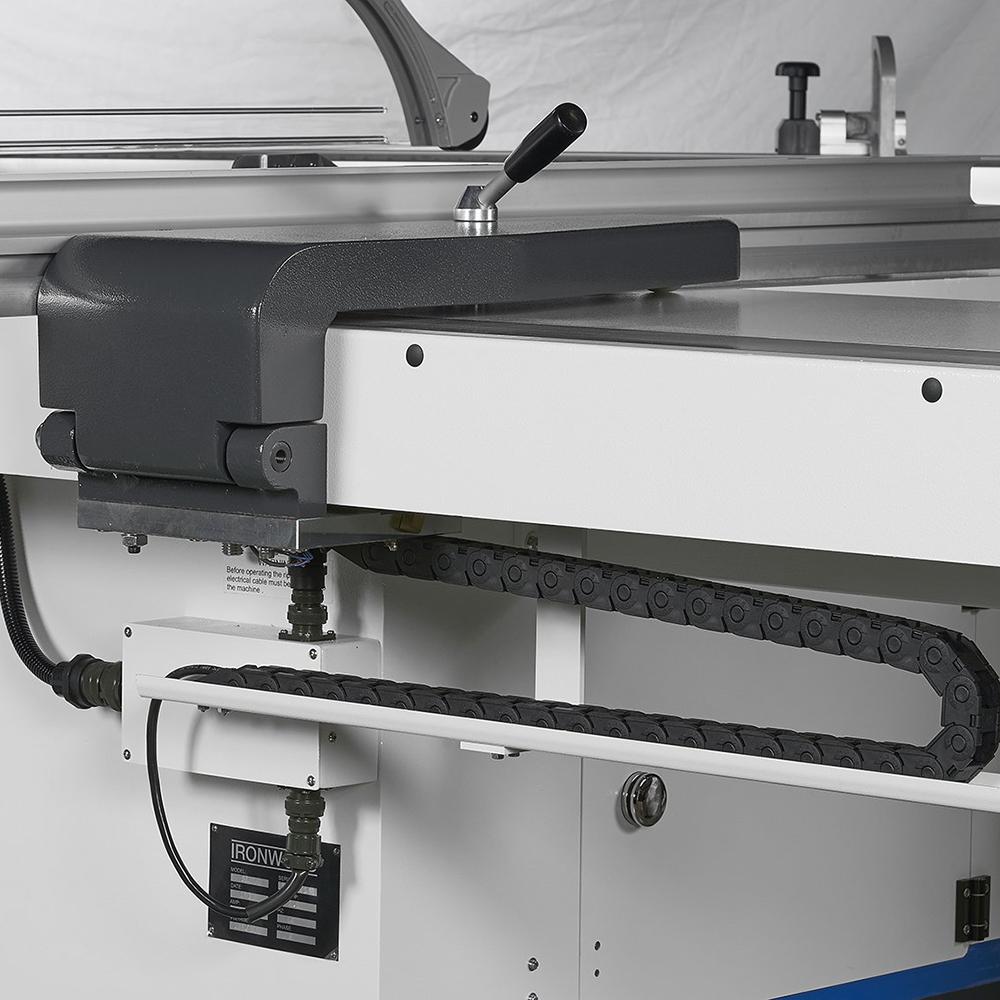

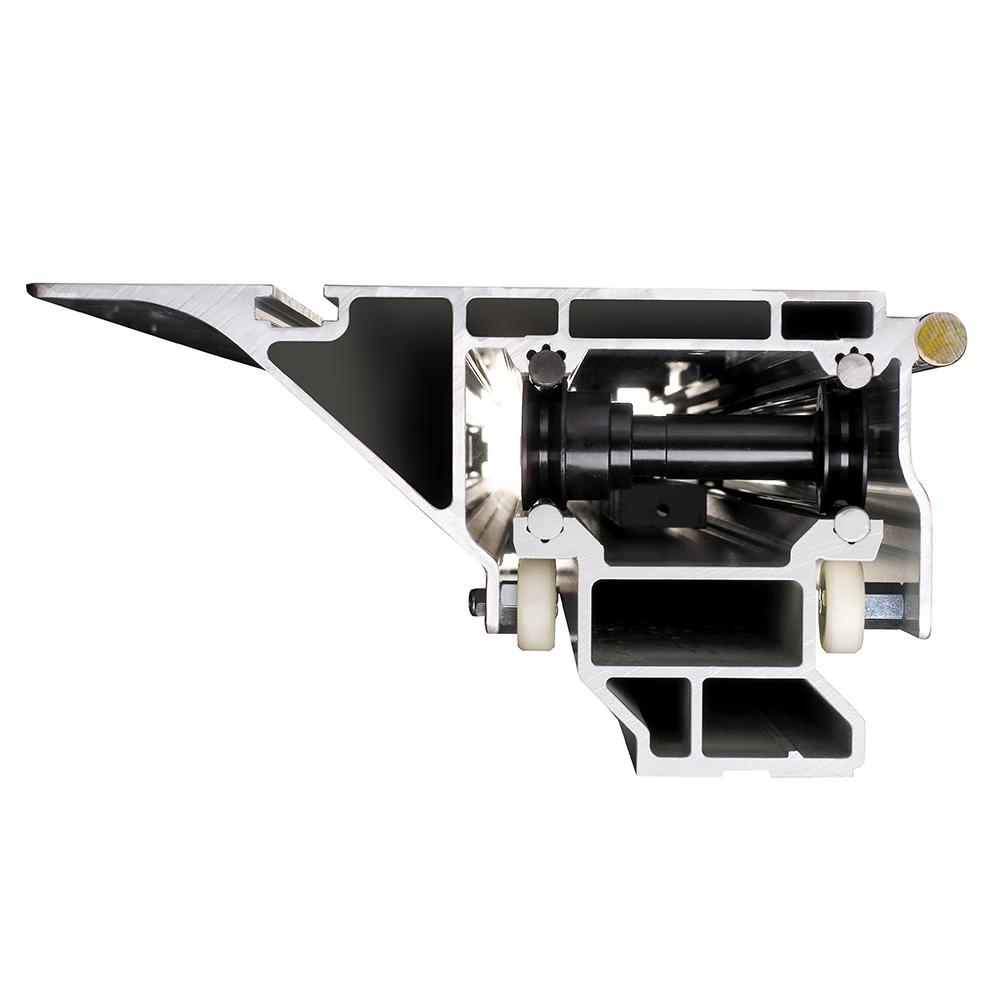

The SL Series features aircraft grade aluminum sliding tables manufactured in Europe with perfected, vertical guidance for accurate, square cuts over the full cutting length. The sliding table’s smooth and precise movement reduces operator fatigue and is totally maintenance free. The chrome hardened guiderails ensure that the sliding carriage traverses straight without lateral movement.

The rugged cast iron frame is robotically welded for absolute precision and strength to support heavy cutting operations. The saw unit is electronically balanced and precisely positioned to provide vibration-free running during the cutting process. In additional to its heavy-duty design, the Ironwood SL series complies with the highest standards of international efficiency by using IE3 motors which reduce energy consumption over the life of the machine and improve global footprint.

-

IRONWOOD’s SL300 is efficient and versatile. Easy to access on and off buttons are located in the overhead controller. A second set of on / off buttons are located at the end of the slider for convenience when sizing larger panels.

SL300 Controller

- Digital readout and motorized axes help operators save time and energy with quick setups, repeatable dimensioning, and pin-point accurate cutting.

- Motorized adjustment for blade height, tilt, and rip fence with digital readouts accurate to 0.1mm or 0.004”

- Displays digital readout for saw speed

- On / Off for main saw and scoring motors with integrated E-stop.

- Blade compensation for height and tilt when mitering

- Digital readout and motorized axes help operators save time and energy with quick setups, repeatable dimensioning, and pin-point accurate cutting.

- 3200mm sliding table for cutting length of 122” with crosscut fence mounted.

- IRONWOOD’s double-roller carriage features a direct vertical load transfer system, to ensure smooth sliding table motion and straight, square, chip free cuts

- Large hardened steel rollers guide the moving table with absolute precision between the hard-chromed guide bars

- Integrated locking mechanism for locking the sliding table in the forward and middle positions

- Maintenance free system requires no oiling, ensuring years of easy movement and accurate cutting even after decades of hard work, dust and dirt.

- Additional sliding table lengths available by special order.

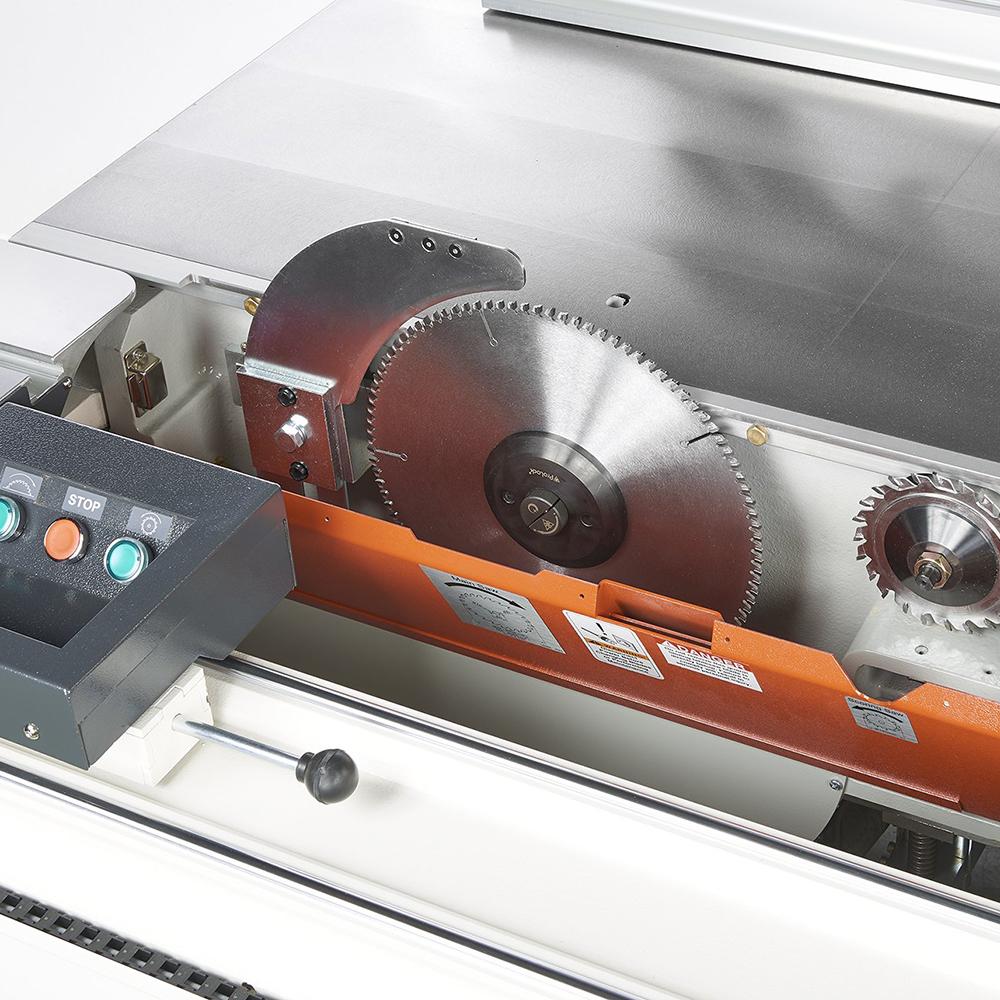

- Main Saw Drive System

- 5 kW (7.5 HP) high efficiency IE3 motor

- Three motor spindle speeds, 3000, 4000 or 5000 RPM adjusted manually

- Cast iron tilt trunnions for precise and smooth tilting

- Tilting Range

- Tilting range 0-45.5 degrees

- Robust tilt trunnions incorporating the traditional tongue and groove connection system for precise and smooth tilting

Extraction Hood

- Overhead extraction hood, including two inserts for straight or miter cuts

- Integrated extraction helps keep the shop floor clean

- Two (2) Axis Motorized Scoring System

- 75kW (1HP), 8,000 RPM

- 120mm / 4.72″ blades (included)

- Motorized height adjustment

- Includes Leitz Quick Adjust Shimless Scoring Unit for easy manual kerf adjustment

- Scoring unit with automatic rise and fall, and manual lateral adjustment is ideal for absolutely chip free cutting of melamine, vinyl, high pressure laminate and veneered particleboard, even when saw blade is tilted.

- Motorized Rip Fence

- 1300mm (51”) rip capacity

- Precision fine adjustment for a high degree of accuracy

- Swing away rip fence, to easily swing rip fence below table level for dividing large pieces

- Automatically adjusts to rip fence when switched from upfront to flat operations

- Easily calibrated

- Achieve superior and repeatable accuracy up to 0.1mm or 0.004”

Crosscut Miter Fence for square or miter cuts

- Crosscut fence with stops to 3200mm (126”)

- Miter angle range can be adjusted over a range of 49°

- Integral manual length compensation to keep flip stops accurate at angle

- Fence can easily be slid from the front to back position without lifting, for easily adjusting the fence for various cutting operations

- Includes two (2) adjustable flip stops

- CNC manufactured, robotically welded, five-sided torsion resistant base with integrated control cabinet

- Easily accessible forklift slot for easy easily moving machine

- Flat machine front for interference free saw operation

- Sliding table two-position lock for the mid-position and end positions

- Electrics according to UL listings

- Emergency stop buttons

- Electric brake on main and scoring motors

- Multiple riving knives included with the machine

- Anodized aluminum parts

- Scales with metric and inch dimensions

- Main and scoring blades included

- Clamping shoe for straight-line rip cuts

- Tool kit and instruction manual

- Three-year warranty mechanical.

- One-year warranty electrical

|

Sliding table length |

3200 mm (126”) |

|

Cutting length |

3105 mm (122″) |

|

Manual rip fence with fine adjust |

1300 mm (51″) |

|

Crosscut miter fence |

3200 mm max second flip stop |

|

Angle Capability Crosscut miter fence |

0º – 49º |

|

Cutting depth maximum |

90° cuts – 125 mm (4.8″) 45° cuts – 85 mm (3.34″) |

|

Main saw motor |

5.5 kW (7.5 HP) IE3 Motor |

|

Saw speed(s) |

3000/4000/5000 RPM |

|

Standard main blade |

305 x 3.2 x 30 mm | Z=100 |

|

Main blade arbor diameter |

30 mm |

|

Scoring saw motor |

0.75 kw (1 HP) 8000 RPM |

|

Scoring blade diameter |

120 mm (4 3/4”) |

|

Tilting Capacity |

0 – 45.5° |

|

Dust channel outlet (saw guard) (machine base) |

76 mm (3”) 100 mm (3.9”) |

|

Dust Extraction |

800 CFM min |

|

Electrical Requirements* |

230V/460V | 3-Phase | 60 Hz |

|

Net machine weight |

1,325 kg (2,921 lbs.) |

*460V power upgrades available upon request. Additional charges may apply.