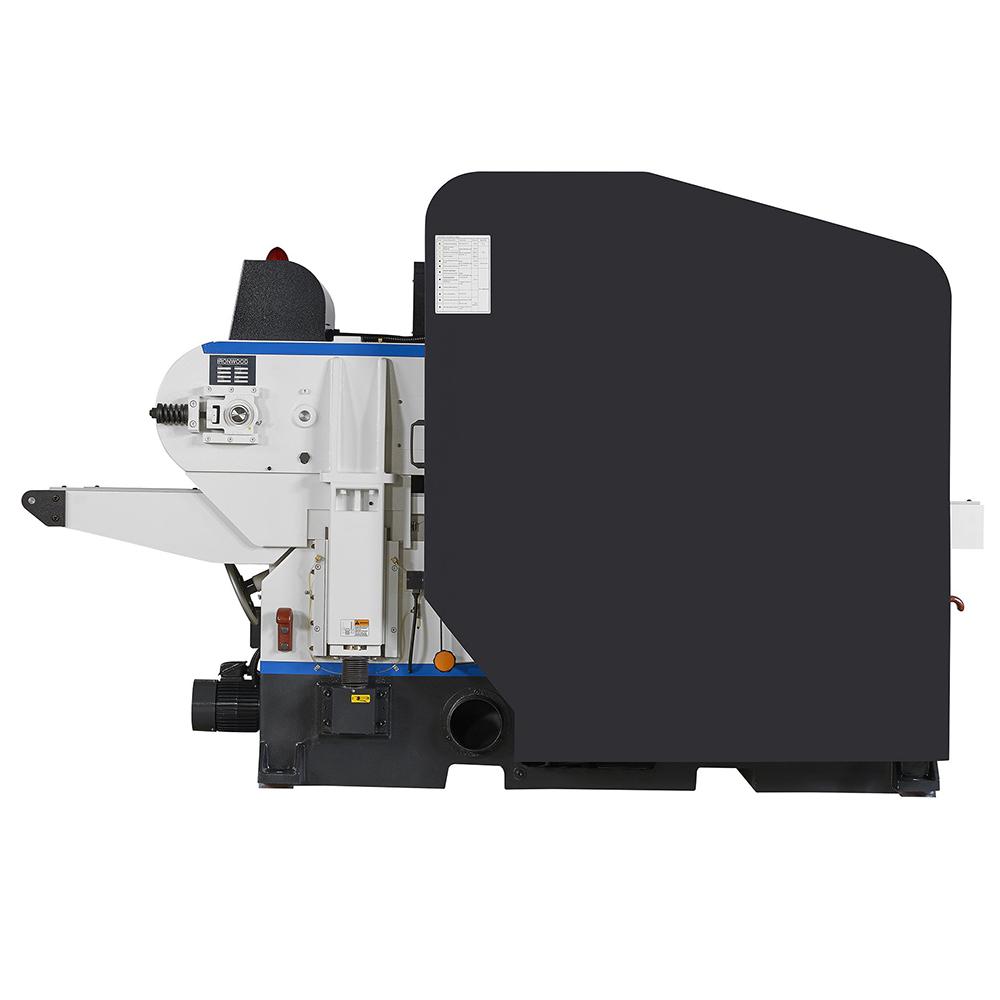

IRONWOOD DSP2500 Dual Surface Planer

The IRONWOOD DSP2500 dual-surface planer offers a heavy-duty, dual sided, planing solution. With chrome plated and precision ground tables, the DSP2500 ensures smooth feeding motion, maximum wear resistance and an unbeatable finish. The robust machine highlights powered table elevation, heavy-duty motors, and an advanced helical cutting system to provide smooth and quiet cutting operations.

- Cutting capacities offer maximum width up to 25” and thickness up to 8”

- Heavy-duty cast iron body and table provides vibration-free operation

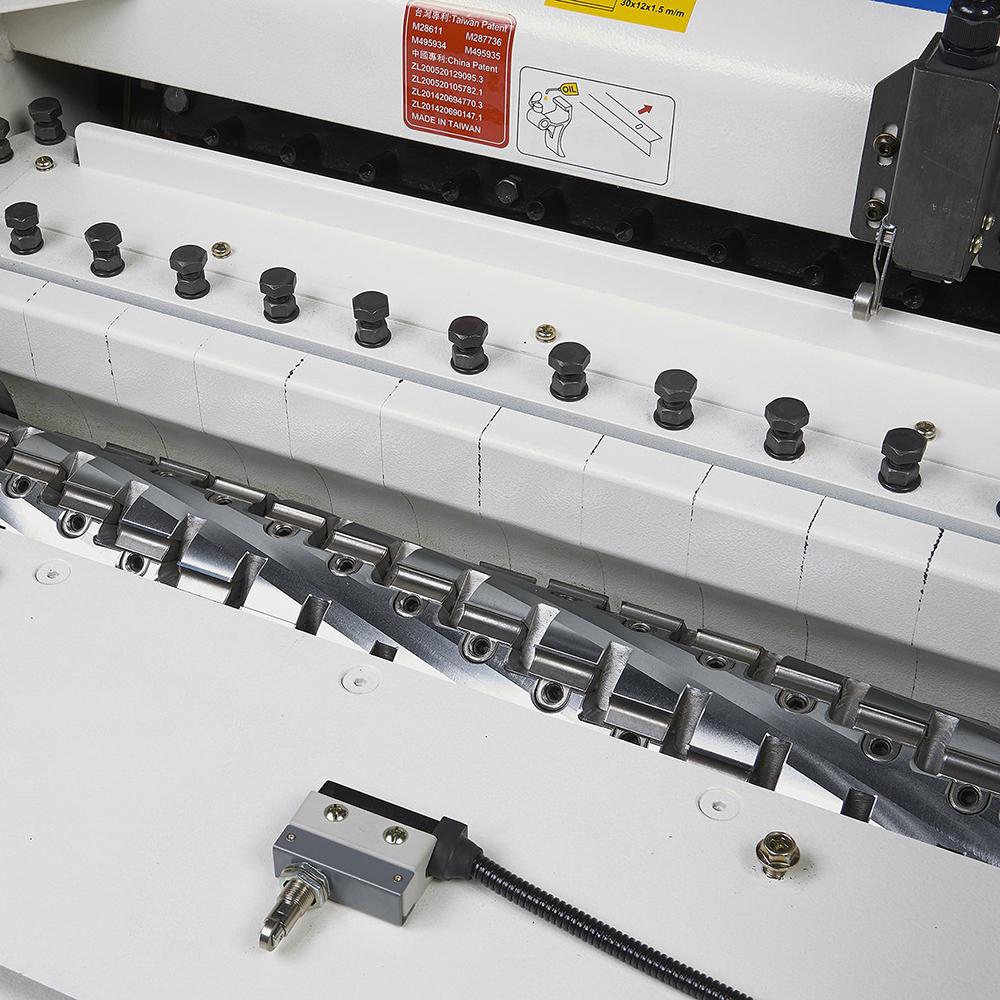

- Overlapped pressure finger feed conveyor secures work pieces firmly and uniformly to maintain straightness and prevent movement

- Micro switch for quick thickness settings

- Powered elevation of upper cutterhead and feed mechanism for convenience and quick settings with fine adjustment

- Dovetail guiderails promise precise and stable table elevation

- Roller chain transmission assembly ensures a smooth and dependable feed as it drives the infeed and outfeed table rollers

- Transmission features torque limiter and variable feed speed controls

- Table is equipped with four powered bed rollers

- Inverter controlled variable feed rates from 26-78 FPM for no loss in power or wearable parts related to feed speed adjustment

- Control panel equipped with programmable thickness readout to 3 decimal places, LED display in inches or mm, motor amp meters, on/off light controls

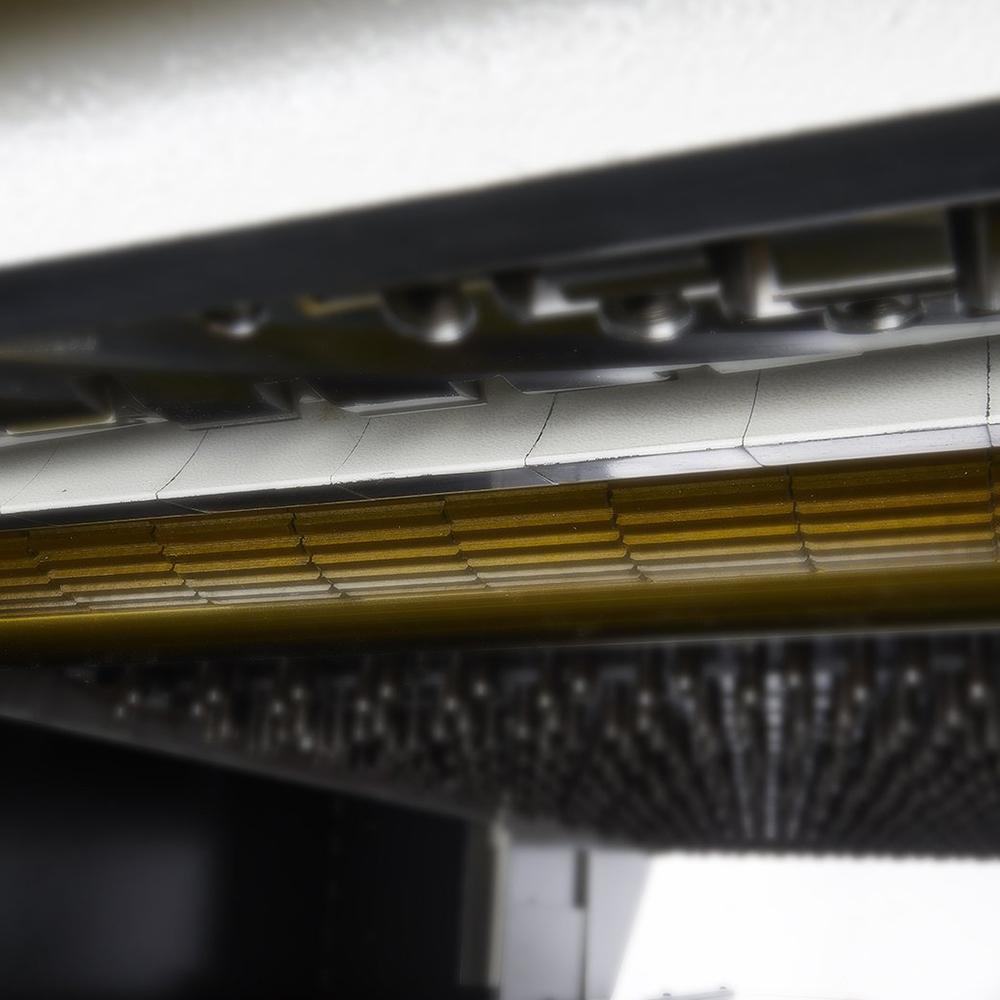

- Heavy-duty spiral cutterheads equipped with dual-sided, rotating, carbide inserts ideal for heavy cutting operations and minimal noise

- Hand wheel adjustment for safe, simple and efficient setting of bottom cutterhead belt tension

- Corrugated, sectional infeed rollers and chip breakers on top head offer optimal performance and minimize breakout

- Adjustment lever offer quick and convenient tensions settings for the pressure spikes on feed carpet

- Automatic lubrication system for feed carpet

- Quick and efficient tooling changeover with pull out lower head. Top head is easily accessible by removing top dust hood.

- Full CE guarding to prevent wood chips from flying out sides of machine and prevent operator access to moving parts

- Safety switches on access covers preventing operation while open

- All electrics feature Schneider Electric components

- Star-delta motor starters for soft starting

- Emergency Stops on front and rear of machine

- One year warranty

| Max working width | 25” (635 mm) |

| Max working thickness | 8” (200 mm) |

| Min working thickness | 3/8” (9 mm) |

| Min length of cut | 12 ½” (310 mm) |

| Upper cutterhead motor | 25 HP |

| Lower cutterhead motor | 20 HP |

| Feed motor | 5 HP |

| Rise/fall motor | ½ HP |

| Variable feed speed | 26-78 F/Min (8 – 24 M/Min) |

| Cutterhead speed | 5000 RPM |

| Cutterhead Ø | 5” |

| Cutter Knives per Head | 96 (192 Total) |

| Knife Insert Size | 30 mm x 12 mm x 1.5 mm |

| Dust extraction | (2) x 6” Ports (1,600 CFM) |

| Machine dimensions | 105” x 45” x 68” |

| Gross machine weight | 7,720 lbs (3500 kg) |

| Electrical Connection | 460V | 3-Phase | 60 Hz. |

*230V power upgrades available upon request. Additional charges may apply.