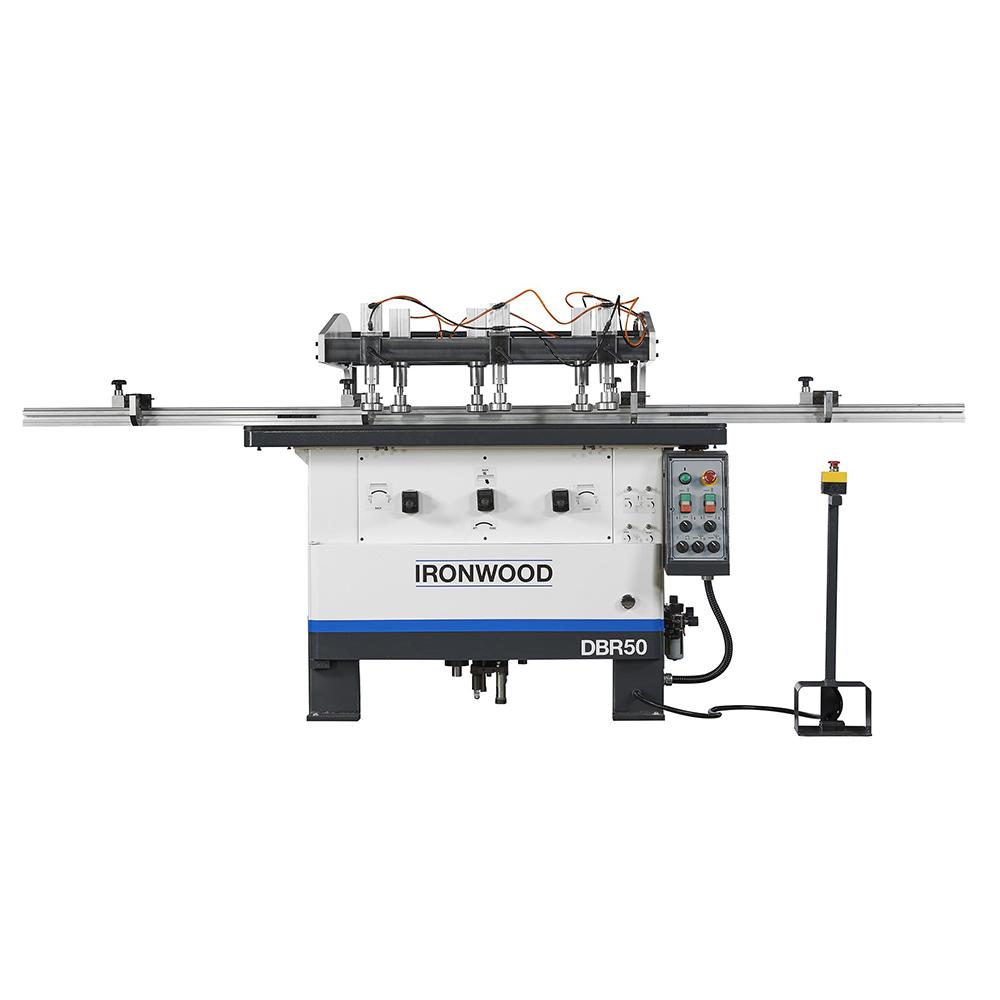

IRONWOOD DBR50 Double Line Boring Machine

The IRONWOOD DBR50 Double-Line Boring machine is an innovative product that incorporates the latest technology and improves efficiency. The unit is ergonomically designed in system 32 for applications which require the drilling of multiple rows in a single function. Catering to the American woodworker, this robust drilling machine boasts quick set-up times, digital readouts for improved accuracy, and a convenient large working surface for all applications.

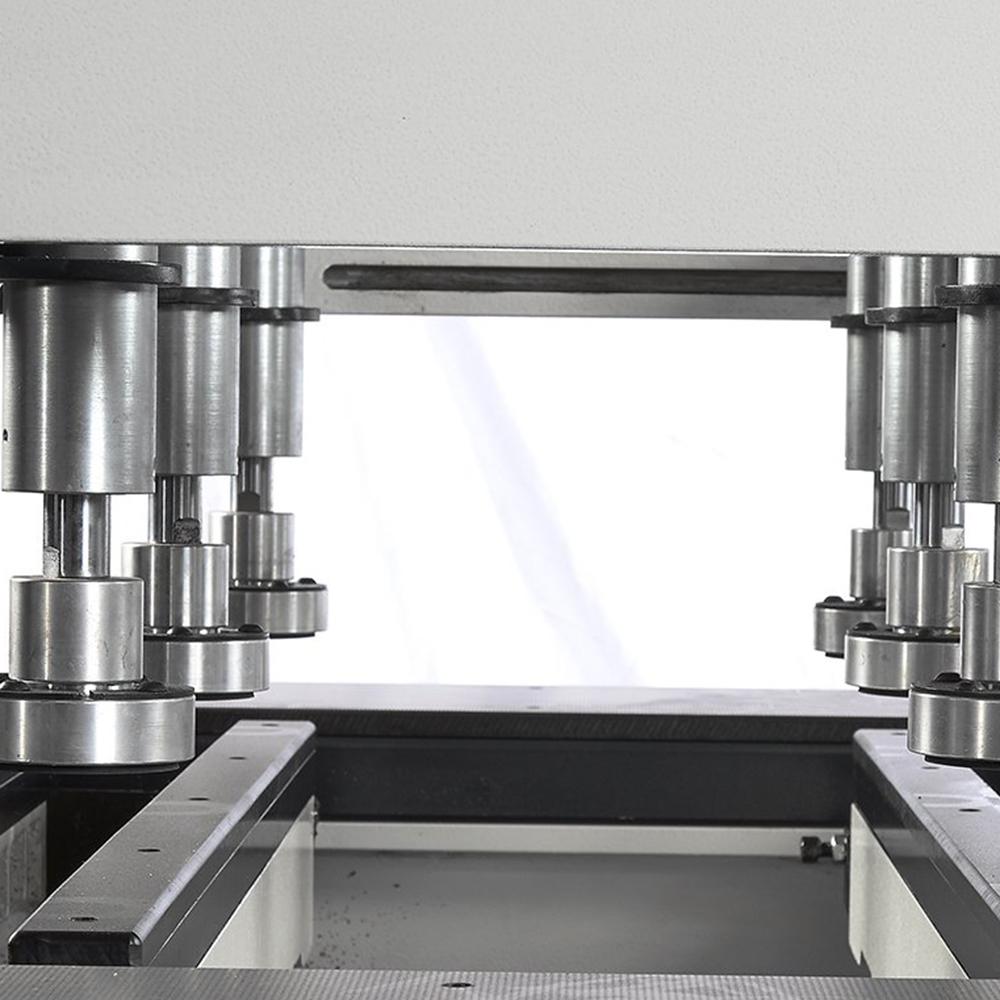

- Dual 25-spindle drill blocks (50 spindles total)

- Accurate positioning of boring unit is easily obtained through digital readout adjustments

- New advanced parallel adjustment of rear fence to drill block with manual release mechanism for quick set-ups of 37 mm and 44 mm settings

- (6) Quick-Release pneumatic clamps to ensure work pieces are secured firmly to the table

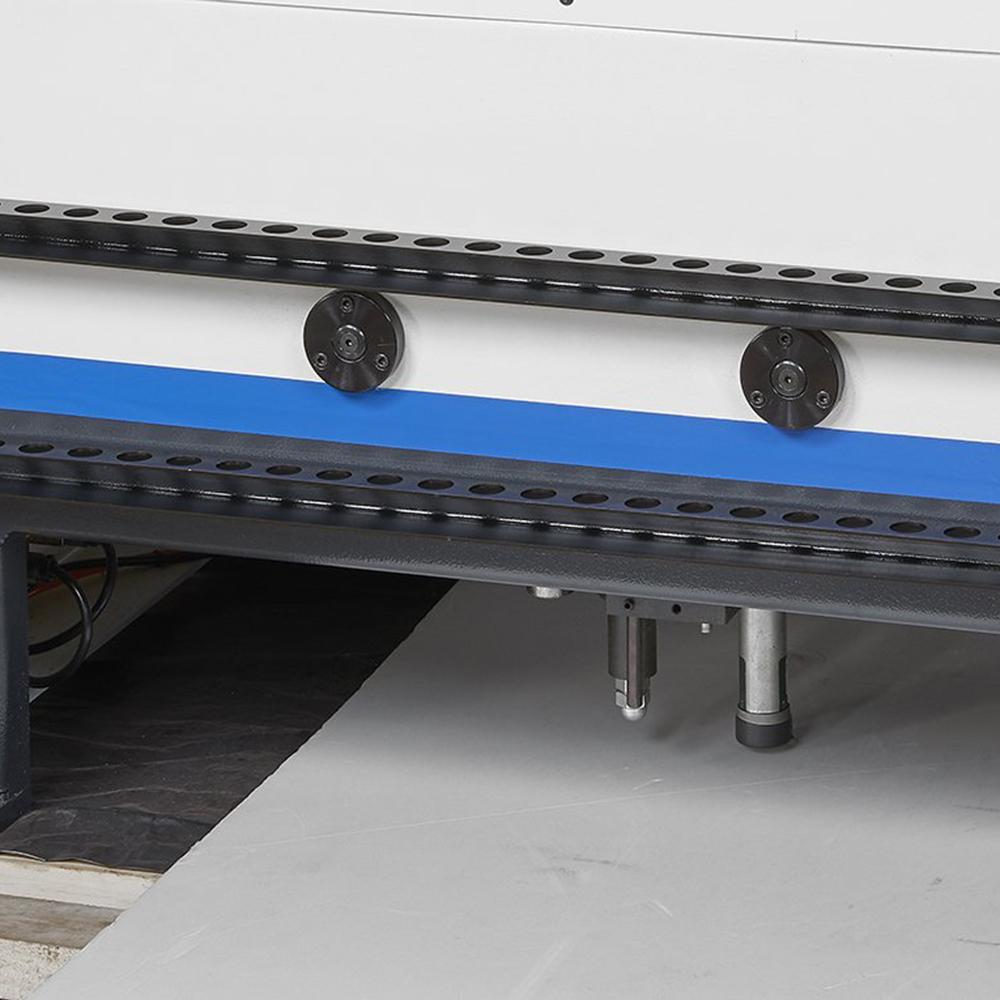

- Robust design of 3000 mm extension fence and heavy-duty, dual-bearing flip stops with hairline readout for improved accuracy and stability

- Analog scales angled for easy viewing with both metric and English measurements; adjustable for quick and easy calibration

- Independently-driven boring units

- Hydro-buffer braking system for fast-slow through drilling operations

- A second measurement scale is integrated into the stopping fence for quick and precise indexing

- Surround tables are accurately positioned allowing for constant drilling height

- Enhanced versatility in offering dual control modes, automatic and manual, designed for work set-up and cycle operations that require repetitive drilling

- Efficiently located depth and positioning adjustments with digital readouts on front panel of the machine

- Drilling feed speed adjustment enables for clean drilling operations of both blind and through hole

- Pivoting control box is adjustable for operator’ convenience

- Innovative design of surround tables offering a large work area for cumbersome applications with compact-micro dot finish to ensure smooth movement of work pieces

- Convenient tool storage door on the front of the machine allows storage of up to (50) additional drill bits

- Access door position on the side of the machine enabling easy access for possible adjustments, maintenance, and cleaning

- Quick-Release pneumatic clamps feature pressure releasing technology to prevent operator injury; clamping pressure is discharged when engaged on a non-flat surface

- Rubber insulated power box preventing exposure to dust

- Two (2) Emergency stops located on foot pedestal and machine controls

- One-year warranty

| Number of boring units | 2 |

| Spindles each boring head | 25 |

| Center distance between spindles | 32 mm |

| Pneumatic clamps per boring head | 3 |

| Distance between boring units | 145 mm to 620 mm |

| Motor power | 3 HP x 2 |

| Dimension of working table | 820 mm x 1150 mm |

| Boring depth | 0 – 70 mm |

| Maximum work piece thickness | 100 mm |

| Quick Chucks Included | 50 unitsz |

| Working height of machine | 33 ¾” |

| Working space requirement (without extension fence) |

55 ½” x 55” x 50 ¼” |

| Net weight | 1,606 lbs. |

| Gross weight | 1,870 lbs. |

| Electrical connection* | 230V | 3-phase | 60 Hz. |

*460V power upgrades available upon request. Additional charges may apply.